Tools for hot forming of steel are high-tech products. They define not only the cost share of the tools as consumables in the production, but are largely responsible for the dimensional accuracy of the formed products. Also, the absence of defects on the product surface can be guaranteed by good tools, only. Several percent of the production, sellable or not, are determined by the tool technology.

In the production of seamless steel tubes special requirements are given specifically to the inner tools, the mandrel bars and the piercing plugs. The tool technology with the optimal selection of the material, the accurate manufacture, the heat treatment, and the surface coating plays a decisive role.

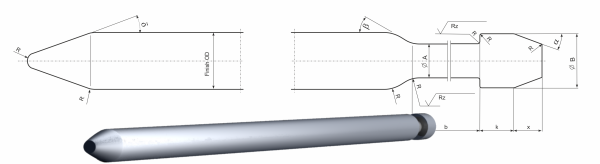

Fig.: Mandrel bar for continuous rolling in the production of seamless steel tubes

To the supply of newly built seamless tube mills in China with high quality mandrel bars DEHUA has made a substantial contribution. It involved the most renowned tool manufacturers in Germany and Italy. In China, the mayor tube plants were supplied. In the period of the economic boom, it was a challenge to provide the tube plants in China in a timely manner with the required qualities. Today, the view to the quality of the tube production in China moves into the focus and hence the stability of the mandrel bars. As before, quality products from Germany are required.

Piercing plugs generate the hollow which develops the first stage of a tubular product from a steel block with solid cross section. They decide on dimensional accuracy and the freedom of defects of the finished products. Required are piercing plugs with long life time, having stability in dimension and surface quality during use. The choice of material and the thermal barrier coating are crucial, but also the operating conditions which include the cooling time and the cooling method.

Modern compact, high-performance production equipment, such as PQF and FQM mills make high demands on the tool technology. DEHUA is engaged in the development of tool technologies and provides mandrel bars and piercing plugs of the world's technologically leading tool manufacturers.

Fig.: Piercer plug for the first stage of the production of seamless steel tubes